Industry News

-

The origin of CNC tools, unimaginable greatness of human beings

The development of knives occupies an important position in the history of human progress. As early as the 28th to 20th centuries BC, brass cones and copper cones, drills, knives and other copper knives had appeared in China. In the late Warring States period (third century BC), copper knives wer...Read more -

CNC common calculation formula

1. Calculation of trigonometric functions 1.tgθ=b/a ctgθ=a/b 2. Sinθ=b/c Cos=a/c 2. Calculation of cutting speed Vc=(π*D*S)/1000 Vc: line speed (m/min) π: pi (3.14159) D: tool diameter (mm) S: speed (rpm) 3. Calculation of feed amount (F value) F=S*Z*Fz F: Feed amount (mm/min) S: speed (rpm...Read more -

Harmful factors of welding materials, what should be paid attention to when using welding materials

Harmful factors of welding materials (1) The main research object of welding labor hygiene is fusion welding, and among them, the labor hygiene problems of open arc welding are the biggest, and the problems of submerged arc welding and electroslag welding are the least. (2) The main harmful fac...Read more -

Generation and Elimination of DC Component in AC TIG Welding

In production practice, alternating current is generally used when welding aluminum, magnesium and their alloys, so that in the process of alternating current welding, when the workpiece is the cathode, it can remove the oxide film, which can remove the oxide film formed on the surface of the mol...Read more -

Why does the machine tool collide Here’s the problem!

The incident of a machine tool colliding with a knife is big and big, let’s say small, it’s really not small. Once a machine tool collides with a tool, hundreds of thousands of tools may become waste products in an instant. Don’t say I’m exaggerating, it’s true. A machine too...Read more -

Have you encountered the following problems?

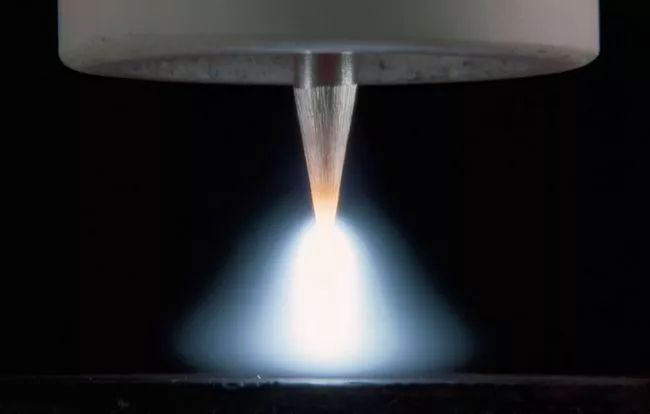

How are drill bits made? What problems will be encountered in drill processing? About the drill material and its properties? What do you do when your drill bit fails? As the most common tool in hole machining, drill bits are widely used in mechanical manufacturing, especially for the machining of...Read more -

Do you have a better method for machining center tool selection skills that increase production efficiency by 50%

Machining centers are widely used in the production of jigs and molds, mechanical parts processing, handicraft engraving, medical device industry manufacturing, education and training industry teaching, etc. The tools selected according to different purposes are also different, so how to choose s...Read more -

Fusion welding, bonding and brazing – three types of welding give you a comprehensive understanding of the welding process

Welding, also known as welding or welding, is a manufacturing process and technology that uses heat, high temperature or high pressure to join metal or other thermoplastic materials such as plastics. According to the state of the metal in the welding process and the characteristics of the process...Read more -

Welding Tips -What are the steps of hydrogen removal treatment

Dehydrogenation treatment, also known as dehydrogenation heat treatment, or post-weld heat treatment. The purpose of post-heat treatment of the weld area immediately after welding is to reduce the hardness of the weld zone, or to remove harmful substances such as hydrogen in the weld zone. In thi...Read more -

Four Key Points for Improving the Technical Level of Pressure Vessel Welding Operation

Important structures such as boilers and pressure vessels require joints to be welded safely, but due to structural size and shape constraints, double-sided welding is sometimes not possible. The special operation method of single-sided groove can only be single-sided welding and double-sided for...Read more -

Welding skills of steel and aluminum and its alloys

(1) Weldability of steel and aluminum and its alloys Iron, manganese, chromium, nickel and other elements in steel can mix with aluminum in liquid state to form limited solid solution, and also form intermetallic compounds. Carbon in steel can also form compounds with aluminum, but they are almo...Read more -

Several welding plugging methods that welders must master

In industrial production, some continuously operating equipment leaks due to various reasons. Such as pipes, valves, containers, etc. The generation of these leaks affects the stability of normal production and the quality of products, and pollutes the production environment, causing unnecessary ...Read more