Industry News

-

Proper Storage of Mig Guns and Consumables

As with any piece of equipment in the shop or on the jobsite, proper storage and care of MIG guns and welding consumables are important. These may seem like rather insignificant components at first, but they can have a big impact on productivity, costs, weld quality and ...Read more -

Preventive Maintenance Helps Optimize Mig Gun Performance

Planned downtime for preventive maintenance in the welding operation is not time wasted. Rather, it is a crucial part of keeping production flowing smoothly and avoiding unplanned downtime. Proper maintenance can extend the life of consumables and equipment, and help pre...Read more -

Mig Welding Basics – Techniques and Tips for Success

It’s important for new welding operators to establish proper MIG techniques in order to achieve good weld quality and maximize productivity. Safety best practices are key, too. It’s just as important, however, for experienced welding operators to remember the fundamental...Read more -

Through-arm Robotic Mig Guns – Top 10 Things to Consider

In recent years, the industry has seen advancements in robotic welding technologies that help companies improve productivity and quality and gain a competitive edge. The transition from conventional robots to through-arm robots is among those advancements. ...Read more -

How to Prevent Common Causes of Poor Welding Wire Feeding

Poor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source of downtime and lost productivity — not to mention cost. Poor or erratic wire feeding can lead to premature failure of consumables, burnbacks, bird...Read more -

Criteria for Selecting a Mig Gun

MIG welding is considered among the easiest welding processes to learn and is useful for a variety of applications and industries. Since the welding wire constantly feeds through the MIG gun during the process, it doesn’t require frequent stopping, as with stick welding....Read more -

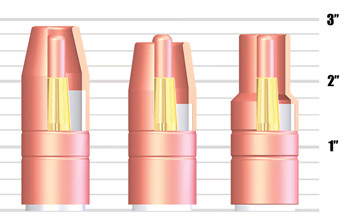

Correct Contact Tip Recess Can Improve Welding Efficiency

In many cases, MIG gun consumables may be an afterthought in the welding process, as concerns with equipment, workflow, part design and more dominate the attention of welding operators, supervisors and others involved in the operation. Yet, these components — particularl...Read more -

A shielding gas guide for GMAW

Using the wrong shielding gas or gas flow can affect weld quality, costs, and productivity significantly. Shielding gas protects the molten weld pool from outside contamination, so it’s critical to choose the right gas for the job. For best results, it’s important to kno...Read more -

Why Do We Need Welding Equipment

Why do we need welding equipment? Welding equipment refers to the equipment required to realize the welding process, including MMA welding machines, MIG welding machines, TIG welding equipment and SPot welding machine, stud welding machines , laser welding mac...Read more -

Tungsten Carbide Thread Milling Cutter for Difficult-to-machine Materials

First, the advantages of thread milling cutter: 1) The thread milling cutter realizes high-precision and high-quality threaded hole processing. When using taps for thread cutting, the accuracy of the bottom hole often occurs, resulting in reduced thread accura...Read more -

Nine Common Phenomena and Treatment Methods of Cnc Tool Wear

CNC tool wear is one of the basic problems in cutting. Understanding the forms and causes of tool wear can help us prolong tool life and avoid machining abnormalities in CNC machining. 1) Different Mechanisms of Tool Wear I...Read more -

What is CNC Machine

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, th...Read more