Industry News

-

Why is titanium alloy a difficult material to machine

Why do we think titanium alloy is a difficult material to machine? Because of the lack of deep understanding of its processing mechanism and phenomenon. 1. Physical Phenomena of Titanium Machining The cutting force of titanium alloy processing is only slightly higher than that of steel with the ...Read more -

The difference between high-speed steel and tungsten steel is very clear!

Come to understand high speed steel High-speed steel (HSS) is a tool steel with high hardness, high wear resistance and high heat resistance, also known as wind steel or front steel, which means that it can be hardened even when it is cooled in air during quenching, and it is very sharp. It is al...Read more -

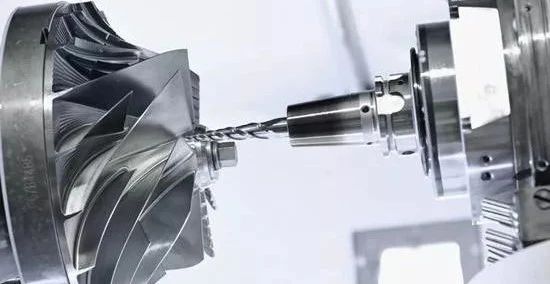

CNC lathe processing skills, so useful!

CNC lathe is a high-precision, high-efficiency automatic machine tool. The use of CNC lathe can improve processing efficiency and create more value. The emergence of CNC lathe enables enterprises to get rid of the backward processing technology. The processing technology of CNC lathe is similar, ...Read more -

What are the methods of non-destructive testing of welds, Where is the difference

Non-destructive testing is to use the characteristics of sound, light, magnetism and electricity to detect whether there is a defect or inhomogeneity in the object to be inspected without damaging or affecting the performance of the object to be inspected, and to give the size, position, and loca...Read more -

Summary of detailed operation methods for welding low temperature steel

1. Overview of cryogenic steel 1) The technical requirements for low-temperature steel are generally: sufficient strength and sufficient toughness in a low-temperature environment, good welding performance, processing performance and corrosion resistance, etc. Among them, the low temperature toug...Read more -

Common Welding Defects and Solutions for Aluminum Alloy Welding

The selection of aluminum and aluminum alloy welding wire is mainly based on the type of base metal, and the requirements for joint crack resistance, mechanical properties and corrosion resistance are comprehensively considered. Sometimes when a certain item becomes the main contradiction, the se...Read more -

The inventions and designs of 25 geniuses all reflect the wisdom and wisdom of human beings!

Someone is inventing a spaceship that will take us to Mars, which is amazing. Equally remarkable are those who work to improve the details of our lives. These designs below are all geniuses! Ukrainian traffic lights where you can’t ignore the signs and can be used as a sight at night This ...Read more -

The basic knowledge of thread gauge, you can earn it when you see it

Basic knowledge of thread gauges A thread gauge is a gauge used to test whether a thread complies with regulations. Thread plug gauges are used to test internal threads, and thread ring gauges are used to test external threads. Thread is an important and commonly used structural element. Threads ...Read more -

A complete collection of steel knowledge, good things are to be shared! !

1. Mechanical properties of steel 1. Yield point (σs) When the steel or sample is stretched, when the stress exceeds the elastic limit, even if the stress does not increase, the steel or sample still continues to undergo obvious plastic deformation. This phenomenon is called yielding, and the min...Read more -

Zero-based hands-on argon arc welding

(1) Start up 1. Turn on the power switch on the front panel and set the power switch to the “ON” position. The power light is on. The fan inside the machine starts to spin. 2. The selection switch is divided into argon arc welding and manual welding. (2) argon arc welding adjust...Read more -

What welding method should be used for welding iron, aluminum, copper and stainless steel

How to weld mild steel? Low carbon steel has low carbon content and good plasticity, and can be prepared into various forms of joints and components. In the welding process, it is not easy to produce hardened structure, and the tendency to produce cracks is also small. At the same time, it is n...Read more -

How to distinguish molten iron and coating during manual arc welding

If it is manual arc welding, first of all, pay attention to distinguish molten iron and coating. Observe the molten pool: the shiny liquid is molten iron, and what floats on it and flows is the coating. When welding, pay attention to not let the coating exceed the molten iron, otherwise it is eas...Read more