News

-

What is the reason for poor weld formation

In addition to process factors, other welding process factors, such as groove size and gap size, inclination angle of the electrode and workpiece, and spatial position of the joint, can also affect the weld formation and weld size. Xinfa welding equipment has the charact...Read more -

What is direct current connection, what is direct current reverse connection, and how to choose when welding

1. DC forward connection (i.e. forward connection method): The forward connection method refers to a wiring method used to measure the dielectric loss factor in the Xilin bridge circuit test. The dielectric loss factor measured by ...Read more -

Basic knowledge of welding process qualification (thermal power generation)

Xinfa welding equipment has the characteristics of high quality and low price. For details, please visit: Welding & Cutting Manufacturers - China Welding & Cutting Factory & Suppliers (xinfatools.com) 1. Concept of weld...Read more -

What is cryogenic air separation nitrogen production

Cryogenic air separation nitrogen production is a traditional nitrogen production method with a history of several decades. It uses air as raw material, compresses and purifies it, and then uses heat exchange to liquefy the air into liquid air. Liquid air is mainly a mix...Read more -

Nitrogen Series Uses of Nitrogen

Applications of nitrogen in various industries 1. Use of nitrogen Nitrogen is a colorless, non-toxic, odorless inert gas. Therefore, gas nitrogen has been widely used as a protective gas. Liquid nitrogen has been widely used as a freezing medium that can be in contact wi...Read more -

Application of nitrogen generator in pharmaceutical industry

Nitrogen generator (also called nitrogen generator) is a device that uses compressed air as raw material and uses an adsorbent called carbon molecular sieve to selectively adsorb nitrogen and oxygen to separate nitrogen in the air. According to different classification m...Read more -

Twelve Rules for Mechanical Injury Prevention

What I recommend to you today are the "Twelve Rules" for preventing mechanical injuries. Please post them in the workshop and implement them immediately! And please forward it to your mechanical friends, they will thank you! Mechanical injury: refers to the extrusion, co...Read more -

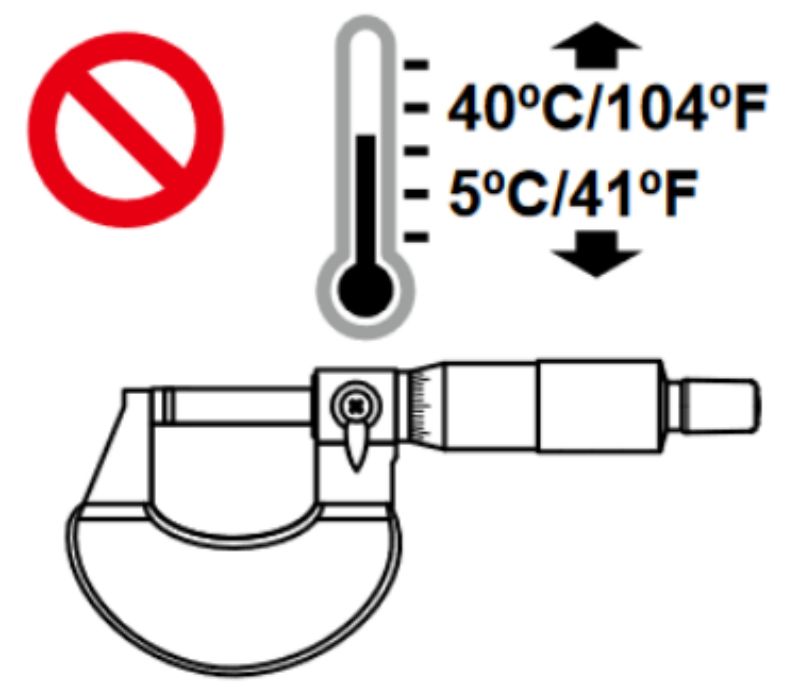

The most taboo uses of micrometers

As a precision measurement tool, micrometers (also known as spiral micrometers) are widely used in precision machining and are well known by people in the industry. Today, let’s change the angle and take a look at what mistakes we are afraid of using micrometers. Xinfa C...Read more -

Machine tool guide rails are generally divided into these categories, do you know

Machine tool manufacturers are doing their best to ensure the accuracy of guide rail installation. Before the guide rail is processed, the guide rail and working parts have been aged to eliminate internal stress. In order to ensure the accuracy of the guide rail and exte...Read more -

The most harmful effects of argon arc welding on the human body are high frequency electricity and ozone. What you must know as a welder

In addition to the same electric shock, burns, and fires as manual arc welding, argon arc welding also has high-frequency electromagnetic fields, electrode radiation, arc light damage, welding smoke, and toxic gases that are much stronger than manual arc welding. The mos...Read more -

How to weld large and thick plates efficiently

1 Overview Large container ships have characteristics such as large length, container capacity, high speed, and large openings, resulting in a high stress level in the middle area of the hull structure. Therefore, large-thickness high-strength ...Read more -

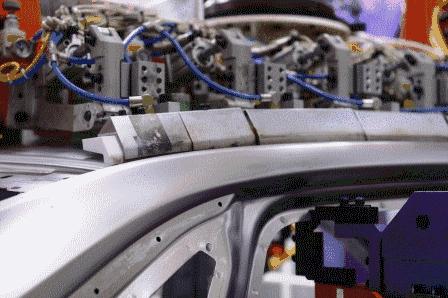

A brief discussion on laser welding process of automobile covering parts

Laser welding process It is particularly valued and widely used in the automotive industry, where automotive panels are one of the five major categories of laser welding. Used in automobiles, it can reduce the weight of the car body, improve the assembly accuracy of the ...Read more