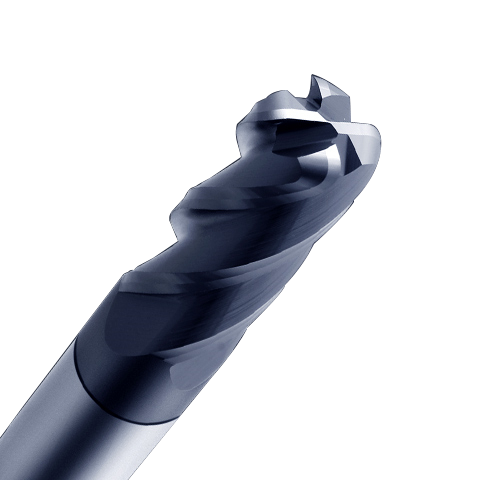

Tools Universal Round Handle Double-Edged Ball Cutter End Mill

|

Type |

Ball nose milling cutter |

Material |

Tungsten Steel |

|

Workpiece Material |

Hardwood, solid wood, mahogany, etc. |

Numerical Control |

Machine tools, advertising engraving machines, CNC machining centers, computer shaving machines |

|

Transport Package |

Box |

Flute |

2 |

Feature

1. Double-edged spiral design, fast chip removal. Large-capacity chip removal port, fast discharge, sharp knife edge, no sticking to the knife

2. HRC55 tungsten steel is sharper, the overall tungsten steel mirror process, high hardness, high wear resistance, sharpness

3. Universal round handle, chamfered design. Easy to use, with good compatibility, tightening does not slip, and higher efficiency

Tool selection

To achieve the purpose you require, please try to use short-edged tools. Too long cutting edge or too long tool body will cause vibration and deflection during machining, resulting in tool damage and affecting machining quality. We recommend using a tool with a larger shank diameter.

Tool operation

1. The woodworking milling cutter is specially designed for portable and desktop woodworking engraving machines, and cannot be used on machines such as electric drills and drill presses.

2. The cutting tool can process a smooth surface on hardwood, softwood, synthetic board and other wood, but avoid processing metal materials such as copper and iron and non-wood materials such as sand and stone.

3. Be sure to use the appropriate size of the jacket, the serious wear is not round enough and the inner hole with a taper jacket can not provide enough clamping force, it will cause vibration or twisting of the tool handle and flying off.

4. Do not think that the new jacket must be safe and reliable. After the tool is clamped, it is found that the handle has uneven contact for a long time or has grooves, indicating slippage and deformation of the inner hole of the jacket. At this time, the jacket should be replaced immediately to avoid accidents.

|

Diameter(mm) |

Shank Diameter(mm) |

Total Length(mm) |

|

0.5 |

6 |

60 |

|

0.75 |

6 |

60 |

|

1.0 |

6 |

60 |

|

0.5 |

6 |

70 |

|

0.75 |

6 |

70 |

|

1.0 |

6 |

70 |

|

0.5 |

6 |

80 |

|

0.75 |

6 |

80 |

|

1.0 |

6 |

80 |

|

0.5 |

6 |

100 |

|

0.75 |

6 |

100 |

|

1.0 |

6 |

100 |

Q1:Can I have a sample for testing?

A: Yes, we can support sample. The sample will be charged reasonably according to the negotiation between us.

Q2:Can I add my logo on the boxes/cartons?

A:Yes,OEM and ODM are available from us.

Q3: What are the benefits of being a distributor ?

A: Special discount Marketing protection.

Q4:How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting or installation process, as well as aftermarket support. 100% self-inspection before packing.

Q5:Can I have a visit to your factory before the order?

A: Sure,welcome your visit of factory.