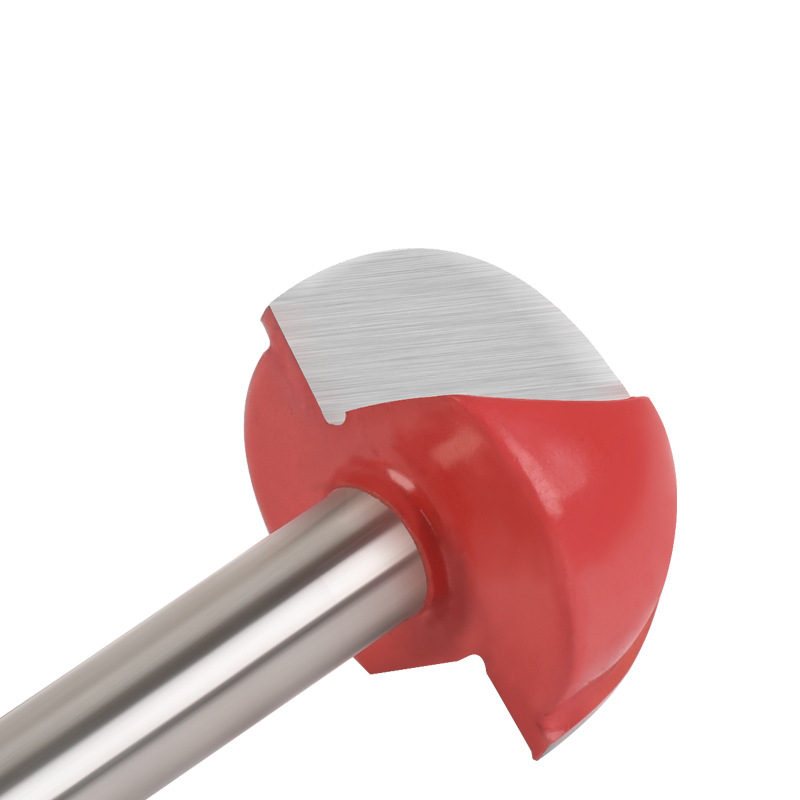

Round Headed Router Bit For Woodworking

Video

Product Description

| Warranty | 1 year | Packing | Plastic Box Packaging |

| Customized support | OEM, ODM | Shank diameter | 6mm |

| Place of Origin | China | Ball head diameter | 22mm |

| Brand Name | XINFA | MOQ | 5 |

| Model Number | XINFA-T141 | Material | Tungsten |

Feature

High Frequency Welding Process

The interface is full of wind, firm and not easy to break

Suitable for wood carving

letter engraving

Acrylic engraving

MDF engraving

Tungsten steel manufacturing, long service life, support customization

No burrs, good chip evacuation, sharp knife edge, wear resistance and durability

Structural stability mature process / beautiful and durable

Customizable quality is reliable

Long life, high durability/ cost-effectiveness

Perfect service, intimate service

Material Tungsten steel

cutting and carving of wood, MDF, etc

Scope of application: automotive industry, aerospace, mold industry, IT industry

Fully specked

1.On-demand customization / more off-the-shelf / reliable quality

2.Preferred material German tungsten steel toughness / knife four sharp

3.Smooth without burrs

The surface is smooth and bright, the amount of chips is large, and the line is fast

4. Wear resistance and high corrosion resistance

No rust and oxidation resistance in humid environments

How to use the woodworking engraving machine tool:

1. Multi-stripe milling cutters are recommended for rough machining of particleboard, etc.

2. A diamond engraving knife is recommended for acrylic mirror engraving.

3. The use effect of the lower cutter, the upper surface of the processed product has no burrs, and there is no rocker during processing.

4. For multi-layer board and splint processing, it is recommended to use double-edged straight groove milling cutter.

5. For high density board and solid wood, it is recommended to use a ribbed cutter.

6. For top and bottom burr-free cutting, it is recommended to use a single-edge, double-edge top and bottom milling cutter.

7. For cork, MDF, virgin wood, PVC, acrylic large-scale deep relief processing, it is recommended to use a single-edged helical ball end milling cutter.

8. For precision small relief processing, it is recommended to use a round-bottomed cutter.

9. For aluminum plate cutting, it is recommended to use a single-edged special aluminum milling cutter. No sticking to the knife during processing, high speed and high efficiency.

10. For MDF cutting, it is recommended to use a double-edged helical milling cutter with large chip removal. It has two

high-capacity chip removal grooves and a double-edged design, which not only has a good chip removal function, but also achieves a good tool balance. When processing medium and high density boards, it has the characteristics of no blackening, no cap smoke, and long service life.

11. For acrylic cutting, it is recommended to use a single-edged spiral milling cutter, which is characterized by smokeless and odorless processing, fast speed, high efficiency, no sticky chips, and truly environmentally friendly. Its special manufacturing process ensures that the acrylic will not explode. , Very fine knife pattern (even without knife pattern), the

surface is smooth and smooth. The machined surface needs to achieve a frosted effect, and it is recommended to use a double-edged three-edged spiral milling cutter.

Q1:Can I have a sample for testing?

A: Yes, we can support sample. The sample will be charged reasonably according to the negotiation between us.

Q2:Can I add my logo on the boxes/cartons?

A:Yes,OEM and ODM are available from us.

Q3: What are the benefits of being a distributor ?

A: Special discount Marketing protection.

Q4:How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting or installation process, as well as aftermarket support. 100% self-inspection before packing.

Q5:Can I have a visit to your factory before the order?

A: Sure,welcome your visit of factory.