Industry News

-

What is the Importance of Stud Welder

The purchase cost of stud welding equipment is relatively low, and there are many types. According to the product, it can be made into a multi-station automatic welding machine or a high-precision CNC automatic welding machine. What is the basic principle of threaded stu...Read more -

What is the Gas cutting machine

The gas cutting of the Gas cutting machine is a metal combustion process: first, the metal is heated above its ignition point with an oxy-acetylene flame, and then the high-pressure oxygen is turned on, the metal will burn violently in the oxygen, and the oxides produced...Read more -

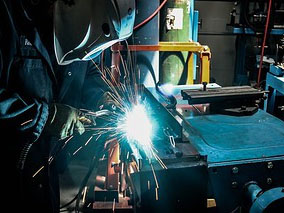

Mig Welding Basics

When it comes to MIG welding, it’s important for new welders to start with the basics to set a solid foundation for success. The process is generally forgiving, making it simpler to learn than TIG welding, for example. It can weld most metals and, as a continuously fed p...Read more -

What Are The Requirements For Stainless Steel Processing Tools

1. Select the geometric parameters of the tool When machining stainless steel, the geometry of the cutting part of the tool should generally be considered from the choice of rake angle and back angle. When selecting the rake angle, factors such as the flute pr...Read more -

9 Reasons Why HSS Taps BREAK

1. The quality of the tap is not good: Main materials, tool design, heat treatment conditions, machining accuracy, coating quality, etc. For example, the size difference at the transition of the tap section is too large ...Read more -

How to Reduce Welding Gun Wear and Extend Gun Life

Knowing the common causes of MIG gun wear — and how to eliminate them — is a good step toward minimizing downtime and costs for addressing issues. Like any equipment in a welding operation, MIG guns are subject to routine wear and tear. The environment and the heat from...Read more -

How carbon molecules work in PSA devices

In the atmosphere, almost 78% is nitrogen (N2) and close to about 21% oxygen (O2) is present. To obtain nitrogen from the air, PSA technology is used by different industries depending on their requirements. Carbon molecular sieves are the core part of pressure swing adsorption (PSA) systems. CMS ...Read more -

How to Prevent 5 Common Welding Gun Failures

Having the right equipment in the welding operation is important — and making sure it works when it’s needed is even more so. Welding gun failures cause lost time and money, not to mention frustration. Like with many other aspects of the welding operation, the most impor...Read more -

5 Ways To Choose The Best Drill Type

Holemaking is a common procedure in any machine shop, but selecting the best type of cutting tool for each job is not always clear. Should a machine shop use solid or insert drills? It is best to have a drill that caters to the workpiece material, produces the specs requ...Read more -

T-Slot End Mill

For high performance Chamfer Groove Milling Cutter with high feed rates and depths of cut. Also suitable for groove bottom machining in circular milling applications. Tangentially installed indexable inserts warrant optimum chip removal paired with high performance at al...Read more -

Solving Common Causes of Welding Porosity

Porosity, cavity-type discontinuities formed by gas entrapment during solidification, is a common but cumbersome defect in MIG welding and one with several causes. It can appear in semi-automatic or robotic applications and requires removal and rework in both cases — lea...Read more -

The Basic Four Principles of Determining the Clamping Force of CNC tools

CNC tool: When designing the clamping device, the determination of the clamping force includes three elements: the direction of the clamping force, the point of action and the magnitude of the clamping force. 1. The direction of the clamping force of the CNC tool The dir...Read more